Viking Pumps

Viking Pumps is one of the most renowned names in the pump business. Over the past 100 years, Viking’s exceptional pumps have been sought after by many businesses and manufacturers, and it’s fair to say that they are a leader and a major player in the industry. In this brand page, Slater Pumps is pleased to introduce you to Viking Pumps and explain some of their products. Let’s take a closer look at everything you need to know about the Viking Pumps brand - read on to find out more!

A brief history of Viking Pumps

Viking Pumps

founded as a company way back in 1911. Since those early days, the company has progressed and become one of the major innovators in the pump industry. Today, thousands of customers from around the world make use of the millions of pumps manufactured by Viking, in all kinds of different sectors.

Make no mistake about it, Viking is a gear pump sector leader, and to this day are still delivering an exceptional pumping experience to a worldwide audience. And much of their success is down to the incredible designs of one of the company’s founders back in the day - the internal gear pumping principal.

According to Viking Pumps, the company was founded on a single pumping principal - ‘gear within a gear.’ And it’s a term that has helped them build a business that is, without doubt, at the top of its field. You can find Viking Pumps across the board, in a variety of industries all over the world. Viking Pumps have been used in the oil sector, the military - even during World War II - and constantly releases new products that meet the needs of their customers.

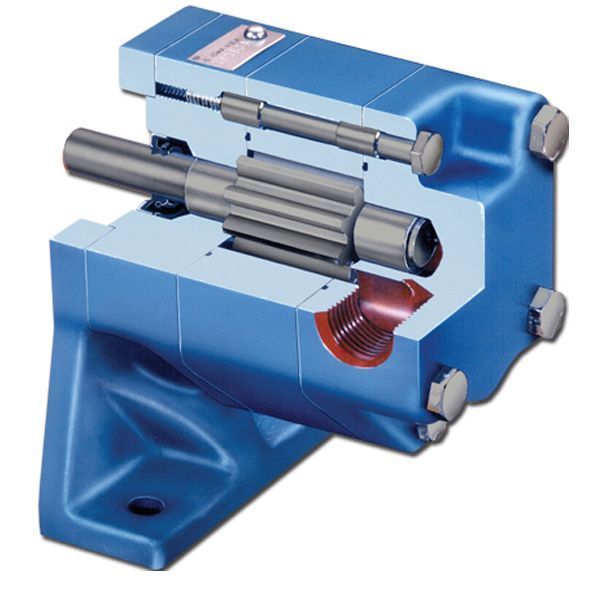

The key technology - Internal gear Viking pumps

It’s a clever piece of technology that remains a key part of Viking Pump’s success. The principle involves using two rotating gears that actually un-mesh the side of the pump where you need suction. The gears are able to create a vacuum, which, in turn, pulls fluid into the pump. Once it is up and running, the spaces on either side of each of the gear teeth move fluid to a crescent on the discharge side. Then, the gears re-mesh on that side, which results in the discharge of the fluid.

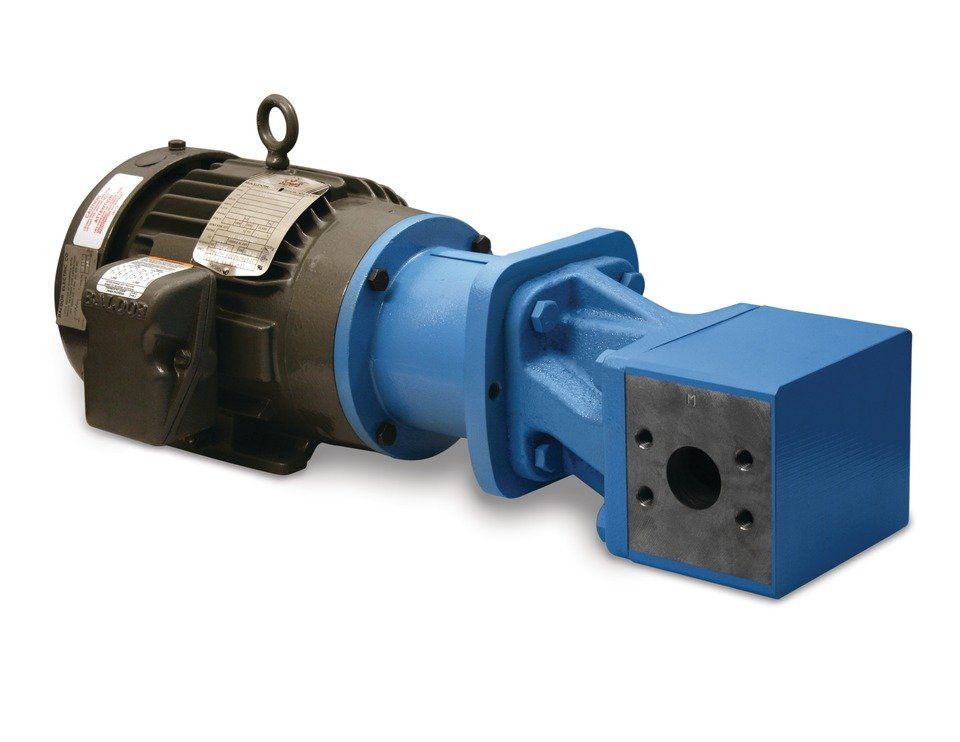

The key technology - External gear Viking pumps

Viking’s external gear pumping equipment is equally as innovative as the internal pumping principle. In this particular pump, there are two rotating gears which un-mesh at the suction side of the pump. In turn, this creates an all-important vacuum that draws in fluid from the pump. Once the fluid starts to come in through each side of the gear teeth, it is moved to the outer area of the housing, which is the discharge side. At this point, the gears kick in, and re-mesh right at the centre of the pump, releasing the fluid. Interestingly, both of the gears are supported by bearings which gives it an extra boost in terms of the pressure the pump discharges.

Key Products

Now, let’s take a look at some of the products that have made Viking Pumps such a successful company, and the go-to folks for any business with pumping requirements.

High-Speed Compact Series Viking Pumps

The Viking High-Speed Compact Series is perfect for businesses needing their pumps for medium and heavy-duty applications. You will find the Viking High-Speed Compact Series used in all kinds of sectors, and it’s often seen in oil recirculation systems, as well as diesel transfer and oil lube systems. The Viking High-Speed Compact Series is designed for a direct drive with 1450, 950 and 720 rpm motors. Expect your Viking High-Speed Compact Series pump to deal with pressure of up to 17 bar and a temperature range between -20 degrees C to 180 degrees C.

Hygienic Series Sanitary Viking Pump

Viking’s Hygienic Series is essential for industries with a focus on keeping up to high standards, including food processing, chemicals, pharmaceuticals and beverage production. As the pump is required to be clean, it is easy to handle and incredibly adaptable. The Hygienic Pump Series comes equipped with all kinds of features, such as a simple one shaft seal - which is just a mechanical or O-ring fitting. Its Fast Clean in Place allows you easy access to ensure hygiene, while the fast Clean Out of Place (COP) enables you to clean the pump while in situ. Finally, the Viking Hygienic Series Pump offers no rotor timing, no shimming, and no need for oil or grease changing.

Abrasive Liquid Viking Pump

In industries that manufacture or use abrasive liquids - such as paints and inks - the Viking Abrasive Liquid Pump is essential. Featuring the ability to handle pressure up to 10 bar, and a temperature of up to 220 degrees C, this is an abrasive pump that is one of the most popular in its field. The Viking Abrasive Liquid Pump comes equipped with Tungsten Carbide bearings and a Silicon mechanical seal. Viking promise that their Viking Liquid Pump has a lifespan of more than double that of a typical gear pump in an abrasive liquid environment.

API 676 Compliant Internal Gear XPD 676 Viking Pumps

The Viking API 676 Compliant Internal Gear XPD 676 Pump is exceptionally popular in the oil industry. You will find the 676 Pump in use in pretty much every area of the sector, including oil refineries, petrochemical plants, and oil terminals. It can take pressure up to 14 bar and will handle the temperature of anything up to 205 degrees C.

External Gear Viking Pump - SG Series

Viking’s External Gear Pump SG Series can be used as a metering pump or even a magnetic pump drive. The SG Series is used in a variety of different industries, including - but not exclusive to - fuels, oils, sealants, paints, and inks. You will also find the SG Series in use with petroleum manufacturers, makers of solvents and chemicals,. Heat transfer businesses and industry that require high levels of reliability and exceptionally high pressure. It’s the perfect pump for use with hazardous liquids - acids and caustics, for example. It’s used extensively in companies that deal with flammable liquids, too, as well as liquids used in heat transfer processes - for instance, in the production of pharmaceuticals. Finally, the SG Series is in use wherever seal failure must be avoided at all costs.

Motor Speed Series Viking Pumps

If you need a pump to use with fine, thin liquids such as refined fuels, processed chemicals or light oils, the Viking Motor Speed Series is your best friend. It has a number of impressive abilities to crow about. Not only can it work with thin oils, but it can also manage to deal with thicker liquids at slower speeds. It’s a versatile pump series that is ideal for any manufacturing or processing situation that results in either chemical reactions or heating/cooling increasing the viscosity of the liquid used. The Motor Speed Series from Viking has a pressure to 17 bar and can deal with temperatures up to 180 degrees. You can buy the Motor Speeds Pumps in a range of sizes, dependent on your requirements, and the range runs from 1” to 6”

Universal Seal Heavy Duty Series Viking Pumps

If your business needs a tough, durable pump that is guaranteed to last the distance, look no further than Viking’s Universal Seal Heavy Duty Series. These are heavy duty pumps that are foot mounted and include very large bearings. This particular feature means you can actually replace seals as and when you need to, without having to take out the pump. The Viking Universal Seal Heavy Duty Series is used in all kinds of different manufacturing situations and is well established as something of a pump industry warhorse. You can expect pressure up to 14 bar, and the series can handle temperatures from a huge range - up to 425 degrees C and all the way down to -85 degrees.

SIngle and Double External Gear Viking Pump

Now, let’s take a look at the perfect example of Viking’s external gear pumps in the field. The Viking SIngle and Double External Gear Pump is designed to work fast at high pressures. You will typically find this particular series in use in low-capacity applications. Again, there’s a wide spread of temperatures that the Viking SIngle and Double External Gear Pump can handle, going as low as -40 degrees C and as high as 260 degrees. The series can also handle the pressure of up to 172 bar.

Viking Pumps are amongst the best in the industry. If you need help choosing the perfect pump for your application, please don’t hesitate to get in touch with Slater Pumps. With years of experience in the pump business, our trained teams will ensure you get the best possible mechanisms for your needs, and we aim to not just meet your expectations - but exceed them. Get in touch with us today to discuss your Viking pump requirements.

For all your new pump needs, simply call our friendly team on 03 9314 4977 now.